Fusion of Laser Metal Deposition and 5-axis Milling The LASERTEC 65 3D is a hybrid solution that incorporates the additive manufacturing function into a 5-axis machining center. Combining laser metal deposition and milling processes on one machine, the LASERTEC 65 3D demonstrates outstanding performance in various applications, such as machining of complex-shaped parts for aircraft and medical.

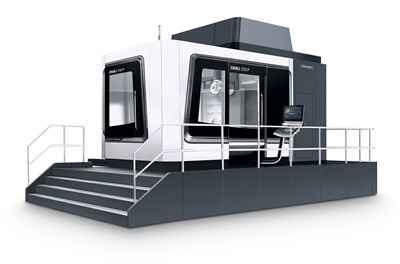

Dmg Mori 3d Print And Mills

High-performance additive manufacturing of metallic 3D-parts

- DMG MORI is a worldwide leading manufacturer of machine tools. The range of products includes turning and milling machines as well as Advanced Technologies.

- The DMG Mori LASERTEC 4300 3D in a all in one industrial 3D printer. This professional 3D printer has integrated laser additive manufacturing into a fully fledged 5-axis mill-turn machine. This hybrid solution combines the flexibility of laser deposition welding with the precision of conventional mill-turn for the additive manufacturing of finished quality parts with maximum precision.

- Laser head integrated in the headstock for higher building volume and more additive performance

- 5-axis material deposition by coaxial nozzle for homogeneous powder distribution, independent of direction of laser deposition welding

- Dedicated additive solution for prototypes, small-series, repair and coating

AM Assistant for the best process reliability and comprehensive traceability

- Integrated thermal imaging camera for observation of the whole working area, adapive process control and constant monitoring of the working distance

- Powder feed rate sensor as well as automatic powder calibration.

- AM Evaluator for visualisation of the relevant process data (e. g. meltpool size, powder mass flow) as a digital 3D-model as well as in the chronological sequence

Siemens NX: Hybride CAD / CAM – Module for additive and subtractive programming

- One software package for the complete process chain (design,

- additive machining, substractive machining, finishing)

- Exclusive LASERTEC build-up strategies - fully integrated in the CAD / CAM software incl. 3D-simulation of machine and movements for collision prevention

- Shorter time-to-market due to completete integrated PLM software integration

Flexibility by utilizing combination of additive and milling machining process for 3D-parts in finished quality

- The laser head is handled by a fully automatic shuttle - without manual intervention

- 5-axis material deposition by coaxial nozzle for homogeneous powder distribution, independent from direction of laser deposition welding

- Full 5-axis milling machine in rigid monoBLOCK-design with < 129.2 ft² footprint

- Process monitoring and adaptive process-control (Closed Loop)

- User friendly and specifically developed software with operator-orientated user interface and CELOS integration

Process monitoring for highest process safety and quality management

- Continuous measuring and monitoring of the laser buildup process as well as automatic regulation of the laser power in real-time for homogeneous part qualities

3d Print Designs

Siemens NX: Complete Hybrid CAD / CAM – Module for additive and subtractive programming

Dmg Mori 3d Print And Mill Machine

- One software package for the complete process chain (design, additive process, substractive machining, finishing)

- Exclusive LASERTEC build-up strategies - fully integrated in the CAD / CAM software incl. 3D-simulation of machine and movements for collision prevention

- Shorter time-to-market due to completeted integrated PLM software integration